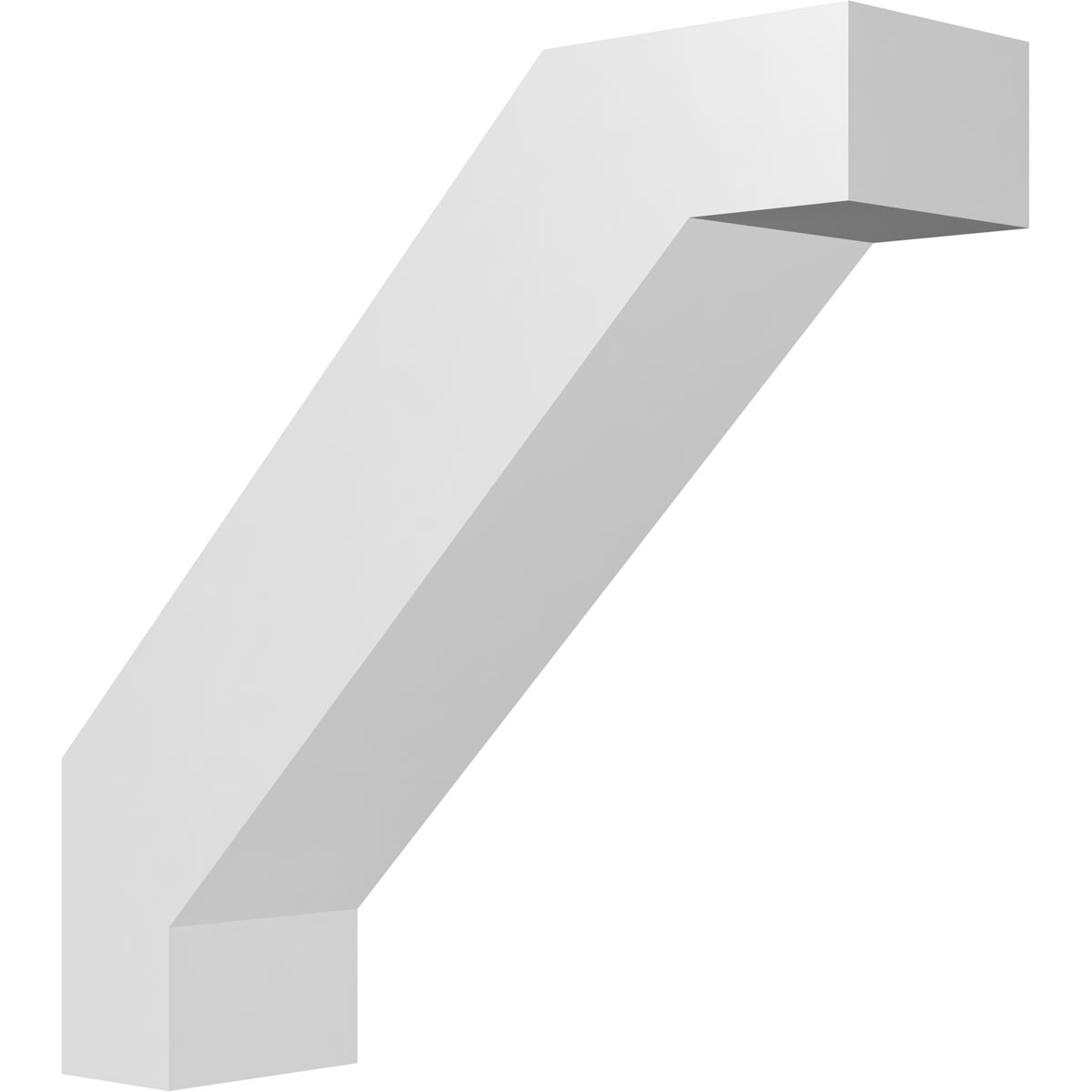

Product Details:

- PVC braces can be used in direct contact with masonry

- Durable PVC braces can be used in direct contact with moisture

- Modeled after original historical patterns and designs

- Decorative PVC braces come in a variety of different styles and sizes

- They can easily be screwed, nailed, or glued for strong, secure installations

- Hand-assembled and sanded in the USA, our white PVC braces arrive ready to paint

$19.00 – $201.00Price range: $19.00 through $201.00

Be the first to review “Ekena Millwork Carmel Architectural Grade PVC Knee Brace”

You must be logged in to post a review.

The Ekena Millwork Carmel Architectural Grade PVC Knee Brace appears to be a specialized product within your line of PVC offerings, designed to serve a specific architectural or construction purpose. Knee braces are structural supports used in building construction to reinforce and support various architectural elements such as overhangs, awnings, porches, or other load-bearing structures.

The term Ekena Millwork Carmel Architectural Grade PVC Knee Brace suggests a higher standard or quality of PVC material used in these knee braces, likely emphasizing its durability, strength, and aesthetic appeal. The “Solid” attribute might indicate that the knee brace is a single, continuous piece rather than being hollow or comprised of multiple components, adding to its sturdiness and stability.

The use of PVC in this context is advantageous due to its weather-resistant properties, low maintenance requirements, and potentially cost-effective nature, especially when compared to traditional building materials.

By offering customizable dimensions and specifications, your product line seems to cater to various construction needs, allowing architects, builders, and contractors to easily integrate these knee braces into their designs while enjoying the benefits of a standardized product offered at customizable dimensions and an affordable price point.

This innovative line of Architectural Grade PVC products sets itself apart by being project-perfect at standard-product pricing. Project-perfect means that you don’t have to go hunting for a standard product to fit your project; you can simply select whatever design you need, pick your width, depth, and height, and we will make you the perfect product at “off-the-shelf” pricing. Manufactured from Architectural Grade PVC, each product is impervious to weather, is maintenance free, and comes with a lifetime warranty.

The characteristics and features of these Ekena Millwork Carmel Architectural Grade PVC Knee Brace are quite impressive:

1. **Direct Contact with Masonry:** The ability to use these braces directly with masonry suggests their durability and resilience in harsh conditions, making them suitable for a wide range of construction applications.

2. **Moisture Resistance:** Highlighting their durability in direct contact with moisture further emphasizes their robust nature, making them suitable for outdoor or damp environments.

3. **Historical Patterns and Designs:** Emulating original historical patterns and designs adds an element of sophistication and aesthetic appeal, making these braces ideal for historical renovations or architectural styles that require a specific look.

4. **Variety of Styles and Sizes:** Offering a variety of styles and sizes ensures adaptability to different architectural designs, allowing for greater versatility in applications.

5. **Ease of Installation:** The option to screw, nail, or glue these braces facilitates a straightforward installation process, enabling secure and robust attachment to various surfaces.

6. **Hand-Assembled and Sanded:** Hand assembly and sanding in the USA likely ensures quality control and attention to detail in the production process, providing a product that’s ready for the finishing touches.

The fact that these PVC braces arrive ready to paint adds another layer of convenience for the end-user, allowing for further customization to match specific color schemes or design preferences. These characteristics collectively make the PVC braces versatile, durable, and aesthetically adaptable for a wide range of architectural or construction applications.

| Select (Width x Depth) | 3"W x 6"D, 3"W x 8"D, 3"W x 10"D, 3"W x 12"D, 3"W x 14"D, 3"W x 16"D, 3"W x 18"D, 5"W x 6"D, 5"W x 8"D, 5"W x 10"D, 5"W x 12"D, 5"W x 14"D, 5"W x 16"D, 5"W x 18"D |

|---|---|

| Select (Height) | 6"H, 8"H, 10"H, 12"H, 14"H, 16"H, 18"H, 22"H, 24"H |

Reviews

There are no reviews yet.